Stress-strain plot will be produced in the test.

Testing setup

Section titled “Testing setup”Follows ASTM Standards E 8 and E 8M. (American Society for Testing and Materials).

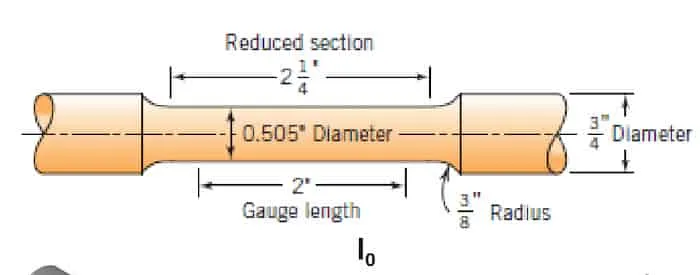

The specimen:

Here

- Gauge length

- Initial diameter

- Initial area

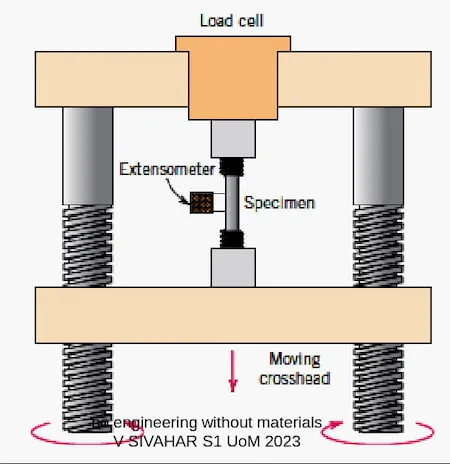

The setup:

Test will be done until the specimen fractures. Results are converted to engineering stress and strain, and plotted.

Load cell

Section titled “Load cell”Measures the force applied to the specimen.

Extensometer

Section titled “Extensometer”Used to measures the elongation (increase in length) in the specimen.

Necking

Section titled “Necking”All deformation up to the maximum point is uniform throughout the specimen.

At this maximum stress, a neck begins to form – known as necking. All subsequent deformation is confined to this neck.

For brittle material

Section titled “For brittle material”The σ-ε behavior of brittle materials cannot be assessed by a tensile test because:

- Difficult to prepare test specimens

- Difficult to grip brittle materials without fracturing them

Hence, fracture strength is specified for engineering design purposes. Tensile strength is calculated from its modulus of rupture (MOR) or flexural strength value.